Windproof dust suppression net is the use of aerodynamic principles, according to the results of the construction site environmental wind speed processing into geometric shapes, opening rate and different hole groups and into windproof dust suppression wall, is the strong wind through the wall, the formation of upper and lower interference air flow in the wall, so as to reduce the wind speed to inhibit the dust flying.

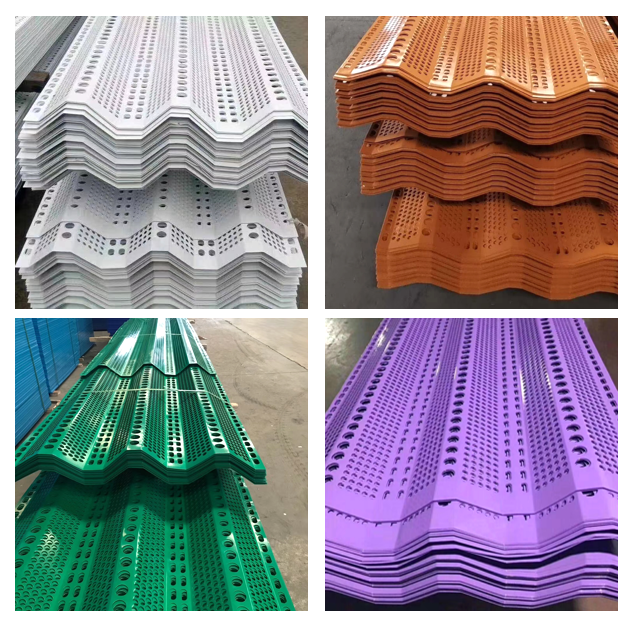

Large open-pit coal mines often cause serious environmental pollution due to the influence of wind. In response to this problem, scientific measures have been taken to build wind and dust suppression nets for coal plants. This not only locks in the pollution caused by fly ash dispersion, but also effectively reduces losses. The so-called wind and dust suppression net for coal plants, also known as wind and dust suppression wall, adopts surface mesh treatment on the wall surface, mostly using low-carbon steel plate, galvanized plate, color coated steel plate, aluminum magnesium alloy plate, and stainless steel plate as materials, mainly used for wind and dust suppression in coal mines, coking plants, power plants, and other coal storage plants.

The characteristics of our company's products for wind and dust suppression nets used in coal plants are as follows:

1. The surface of anti ultraviolet (anti aging) products is treated with spray molding, which can absorb ultraviolet rays from sunlight, reduce the oxidation rate of the material itself, and make the product have good anti-aging performance and longer service life. At the same time, the UV transmittance is low, avoiding damage to the material caused by sunlight.

2. Flame retardancy: Because it is a metal plate, it has good flame retardancy and can meet the requirements of fire protection and safety production.

3. Impact resistant products have high strength and can withstand the impact of hail (strong winds). Impact strength test is conducted on the upper and middle parts of the sample, using a 1kg steel ball that falls freely at a height of 1.5 meters from the peak of the wave. The product has no broken or penetrated holes.

4. The surface of anti-static products is treated with electrostatic spray molding. After being exposed to sunlight, it can oxidize and decompose organic pollutants attached to the product surface. In addition, its super hydrophilicity makes dust easy to be washed by rainwater, achieving self-cleaning effect without maintenance costs.

Post time: Mar-08-2024