Fingerprint-resistant coating, also called PC coating, is a permanent anti-corrosion coating. This extremely thin transparent organic coating film not only has anti-corrosion and fingerprint resistance properties, but can also improve stamping lubricity during molding and processing. , and can be used as the adhesive base layer for subsequent coatings;

As early as the 1980s, Japan's Nippon Steel, Nippon Steel Pipe, Kawasaki Steel and other steel companies have begun to produce electro-galvanized fingerprint-resistant steel plates. Due to the high production cost of electro-galvanizing, the price is also high. With the development of hot-dip galvanizing technology, the quality of hot-dip galvanized products, especially the surface quality, continues to improve, making hot-dip galvanized sheets increasingly used in the fields of automobiles and home appliances. widely. There has been a demand in the market to replace electro-galvanized sheets with hot-dip galvanized sheets. At present, the research and development of hot-dip galvanized fingerprint-resistant steel plates has begun to take shape, and its output is not expanding, and it is likely to replace electro-galvanized fingerprint-resistant steel plates.

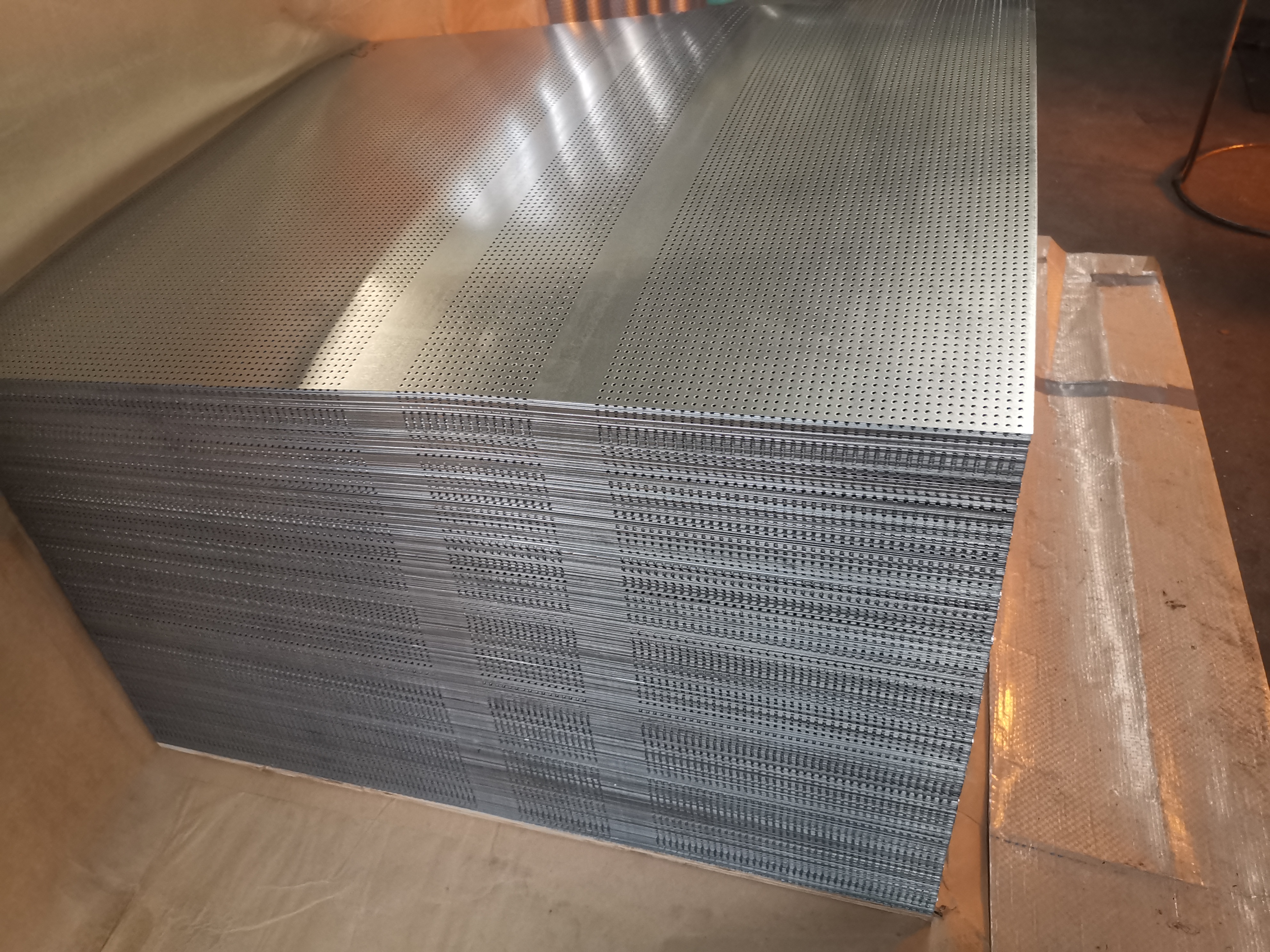

After the hot-dip galvanized sheet has been controlled and smoothed, its surface roughness is 0.9-1.5mm. This product with a rough surface is prone to leaving sweat stains on the surface of the galvanized sheet during production, transportation and use. And fingerprints: Because sweat stains are acidic substances, galvanized sheets are prone to rust in areas with sweat stains and fingerprints, affecting the appearance of the product. Although it has been coated, sweat stains and fingerprints will still reveal dark spots, so it must undergo fingerprint-resistant post-processing.

Post time: Dec-20-2023