Shelf backboard punching mesh can be made of cold-rolled plates, hot-rolled plates, manganese steel plates, stainless steel plates, aluminum plates and other materials. Generally, they are produced using iron plates. When the thickness of the selected plate is relatively thin, it can Cold-rolled plates are used. Generally, cold-rolled plates are used when the plate thickness is less than 3mm. The shelf back panel punching mesh made of cold-rolled plates has the characteristics of high surface finish, low cost, wear resistance and high hardness.

When the selected plate thickness is ≥3mm, hot-rolled plates or manganese steel plates are mostly used. Hot-rolled plates have high carbon content and good ductility. They are very suitable materials for back plates that require bending; manganese steel plates Compared with hot-rolled plates, it has higher wear resistance and longer service life.

Stainless steel plates are used as shelf backplane perforated mesh, which is generally used in high-end places such as large shopping malls and office buildings. Stainless steel shelf backplane perforated mesh is expensive, but has a long service life and will never rust. The surface is polished or brushed, which is very elegant and beautiful.

The use of aluminum plates as shelf backplane perforated mesh is generally suitable for special environments. The aluminum plate perforated mesh has a sound-absorbing effect.

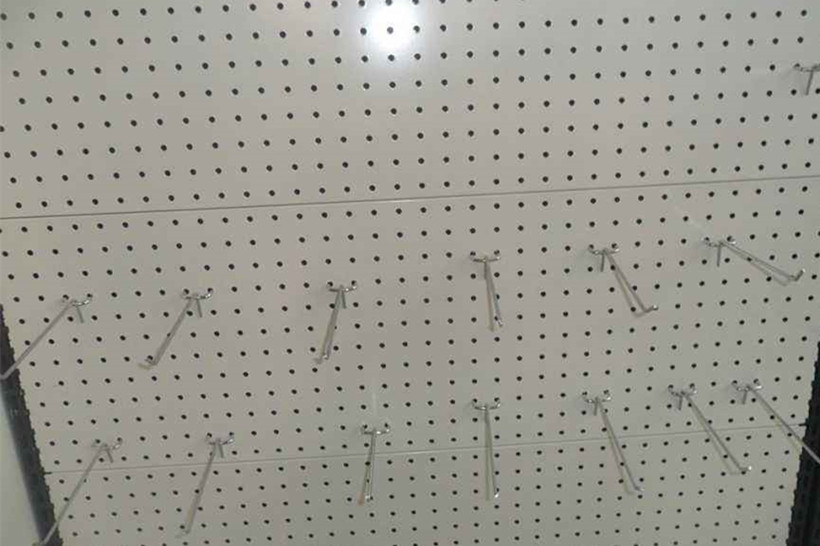

Advantages of punched mesh as shelf backboard

1. Beautiful and elegant: The punching mesh holes have a variety of arrangements and can be customized into various hole types.

2. Ventilation and breathability: The perforated mesh has many small holes, which can effectively ventilate and breathable.

3. Strong bearing capacity: The punching mesh adopts a variety of arrangements, which can effectively improve the bearing capacity of the original board.

4. Save materials: The use of perforated mesh for shelf backplanes can save a lot of production costs and man-hours. In the past, the shelves were made of pure iron plates, and then hooks were made on them. Nowadays, perforated mesh is used as the backplane to directly match Just use a universal hook.

5. Beautiful colors: The perforated mesh for the shelf backboard adopts electrostatic powder spraying technology, and there are many choices in color selection. Theoretically, any color can be mixed and sprayed.

6. Diversity of material selection: Shelf back panel punching mesh can be made of cold-rolled plates, hot-rolled plates, manganese steel plates, stainless steel plates, aluminum plates and other materials.

Post time: Apr-09-2024