Aluminum plates are usually divided into the following two types:

1. According to the alloy composition, it is divided into: High-purity aluminum plate (rolled from high-purity aluminum with a content of more than 99.9) Pure aluminum plate (component is basically rolled from pure aluminum) Alloy aluminum plate (composed of aluminum and auxiliary alloys, usually aluminum Copper, aluminum manganese, aluminum silicon, aluminum magnesium, etc.) Composite aluminum plate or welded plate (special-purpose aluminum plate material is obtained by combining multiple materials) Aluminum-clad aluminum plate (the outside of the aluminum plate is covered with a thin aluminum plate for special purposes)

2. Divided by thickness: (unit mm) thin plate 0.15-2.0, conventional plate 2.0-6.0, medium plate 6.0-25.0, thick plate 25-200, extra thick plate 200 or more

3. Uses of aluminum plates: 1. Lighting 2. Solar reflective sheets 3. Building appearance 4. Interior decoration: ceilings, walls, etc. 5. Furniture, cabinets 6. Elevators 7. Signs, nameplates, bags 8. Car interior and exterior decoration 9 .Interior decorations: such as photo frames 10. Household appliances: refrigerators, microwave ovens, audio equipment 11. Mechanical parts processing 12. Mold manufacturing.

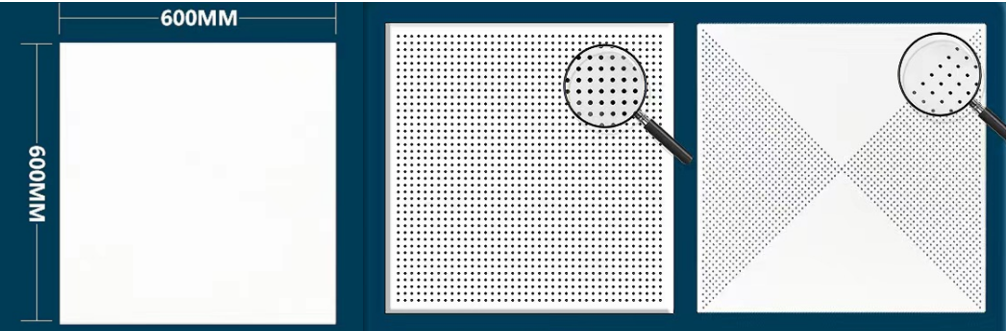

Aluminum alloy punching mesh and exterior wall punching and oxidized curtain wall are made of high-quality aluminum alloy as the base material and are processed by die stamping or engraving machine. The exterior wall punching curtain wall can be processed by oxidation surface treatment or fluorocarbon spraying. Prismatic punching Perforated mesh panels, designated exterior wall products for 4S stores, perforated aluminum panels for exterior walls dedicated to 4S stores, various special-shaped curtain walls, hyperbolic curtain wall panels, shaped curtain wall panels, can be processed and produced according to the design drawings of various brands of automobile 4S stores, various panel types , various punching hole diameters, and coating colors can be customized at will. Advantages of aluminum alloy perforated mesh: Aluminum alloy perforated mesh is light in weight, has good rigidity, high strength and reasonable structure. Wind pressure deformation resistance, rainwater leakage resistance, air leakage resistance, and seismic resistance performance can all meet the structural design requirements. The surface coating has strong weather resistance and long-lasting color; it has good fire protection performance and excellent corrosion resistance. It is flexible and convenient for construction workers to install. , fast, easy to maintain; not easy to pollute, easy to clean and maintain.

Features of aluminum alloy punching mesh:

(1) Fireproof, anti-static, easy to install. It is convenient for inspection and saves the cost of keel construction. Special specifications can be customized at will. Direct supply from the manufacturer. Welcome to inspect.

(2) Light weight, good rigidity, high strength and good corrosion resistance.

(3) Different scheme combinations can be selected to make the design ever-changing and various decorative effects can be designed;

(4) Each allegro is independent and can be installed and disassembled at will, without the need for special tools, which is convenient for maintenance and repair;

(5) Stretch and bend arcs and various shapes to create more unique and beautiful works

(6) The visual height of the upper space can be flexibly adjusted

(7) The trapezoidal shape is full of three-dimensionality, densely assembled and installed, beautiful, novel and generous, and easy to install and disassemble.

Post time: Mar-11-2024