Many customers are unsure about the material when purchasing perforated mesh products. They don’t know which material to choose is economical and affordable. Here is a brief introduction to the difference between carbon steel and stainless steel?

Steel is a general term for iron alloys with a carbon content between 0.02% and 2.04%. The chemical composition of steel can vary greatly. Steel containing only carbon elements is called carbon steel (carbon steel) or ordinary steel. In actual production, steel often contains different alloying elements according to different uses, such as: manganese, Nickel, vanadium, etc.

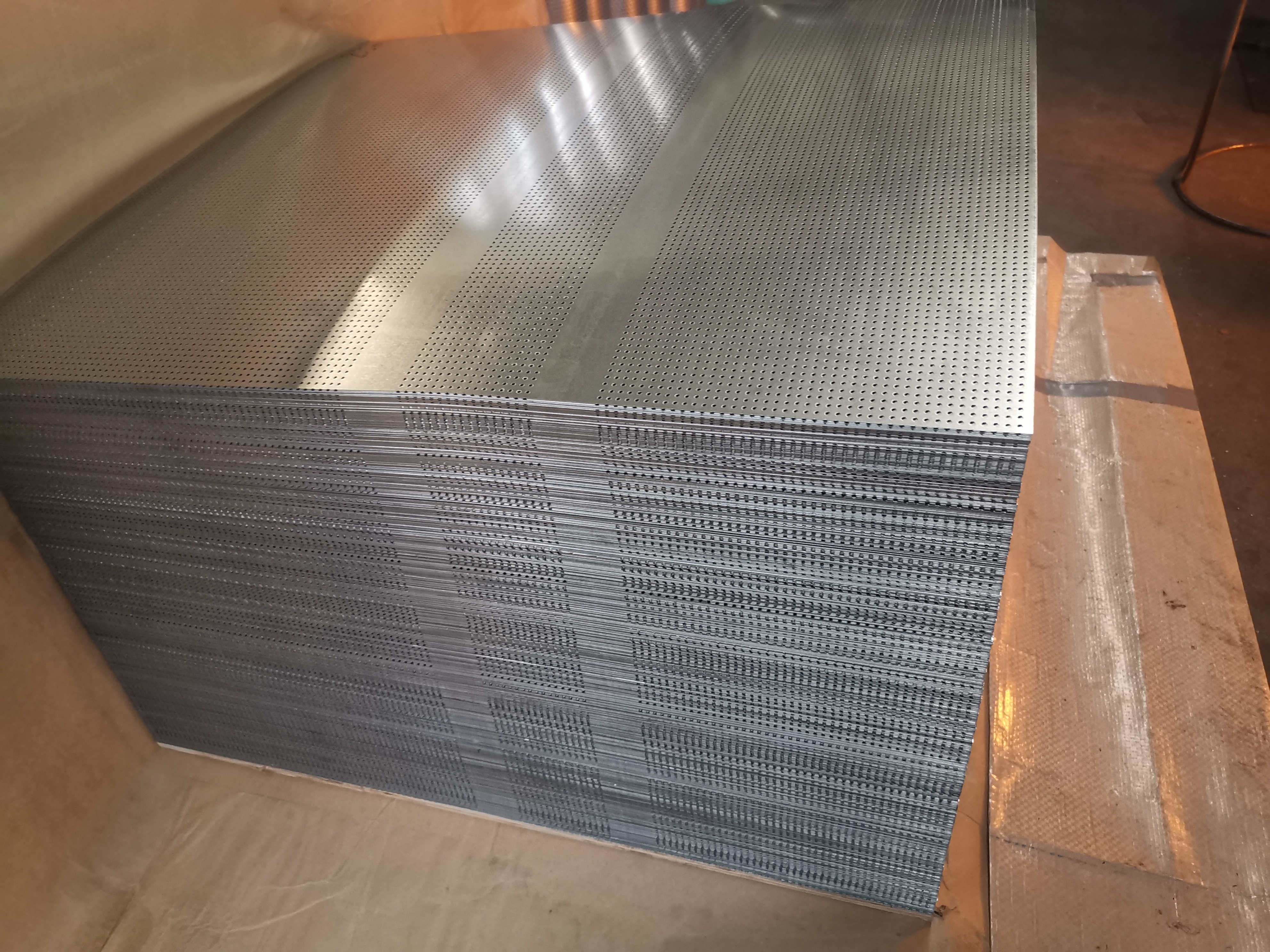

Carbon steel is often referred to as carbon structural steel. According to the carbon content, it can be divided into low carbon steel, medium carbon steel and high carbon steel. The carbon content is 0.2-0.7% or even higher. Carbon steel is generally not corrosion resistant and is used in a variety of structures due to its low price (relative to stainless steel). Stainless steel refers to alloy steel that is resistant to corrosion by weakly corrosive media such as air, steam, and water and chemically corrosive media such as acids, alkali, and salts. The corrosion resistance of stainless steel depends on the alloying elements contained in the steel. The basic alloy elements of stainless steel include nickel, molybdenum, titanium, niobium, copper, nitrogen, etc.

Stainless steel is used in highly corrosive media, especially in food, pharmaceutical, daily chemicals, cosmetics and other industries that require higher environmental conditions. Of course, the chemical industry is also widely used. Carbon steel is low in cost, easy to rust, and has a short service life, while stainless steel is not easy to rust, has a long service life, and has a smooth surface. The addition of the above alloy elements greatly improves the oxidation resistance and thermal stability, but these alloys are all precious metals. So the price is relatively high.

Post time: Feb-20-2024