Introduction: Stainless steel wire mesh is made of high-quality stainless steel wire that is stretched to a specified wire diameter by a wire drawing machine under specific high-temperature process conditions, and then woven by a knitting machine in a constant-temperature, dust-free, clean factory.

Features: Precision structure, uniform mesh, good filtration accuracy, wear resistance, high temperature resistance, strong acid resistance and corrosion resistance.

Material: SUS302, 304, 304L, 316, 316L, 430, 430A, etc.

Performance parameters: High-mesh stainless steel wire mesh 325 mesh-635 mesh (high-density stainless steel filter), ordinary stainless steel wire mesh 8 mesh-300 mesh.

Width: 1 meter - 8 meters (can also be cut into 0.05-0.99 meter mesh according to user requirements).

Weaving methods: plain weave, twill weave, dense weave, contrast weave, five-harness weave. Among them, dense weave includes plain weave - dense weave, twill weave - dense weave.

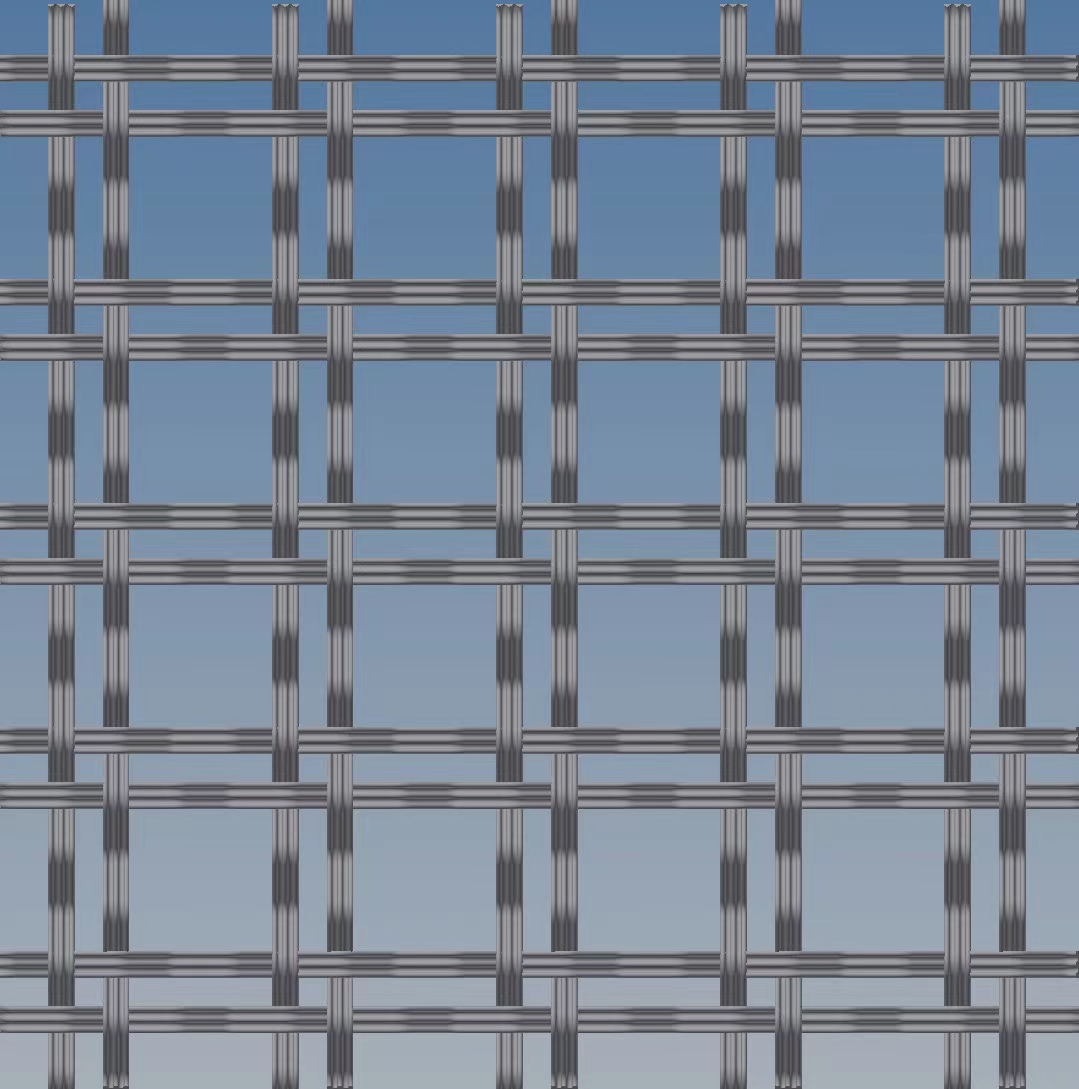

Plain weave: A weaving method in which each warp wire crosses up and down each weft wire, the diameter wire is the same thickness as the weft wire, and the warp wire and weft wire are at an angle of 90 degrees.

Twill weave: A weaving method in which each warp wire crosses above and below every two weft wires, and each weft wire crosses above and below every two diameter wires.

Sheet net plain weave: a weaving method in which each diameter wire crosses up and down a weft wire, and each weft wire crosses a diameter wire up and down. Warp threads are thicker than weft threads.

Mat mesh twill weave: Each diameter wire passes above and below every two weft wires crosswise, and each weft wire crosses above and below every two diameter wires.

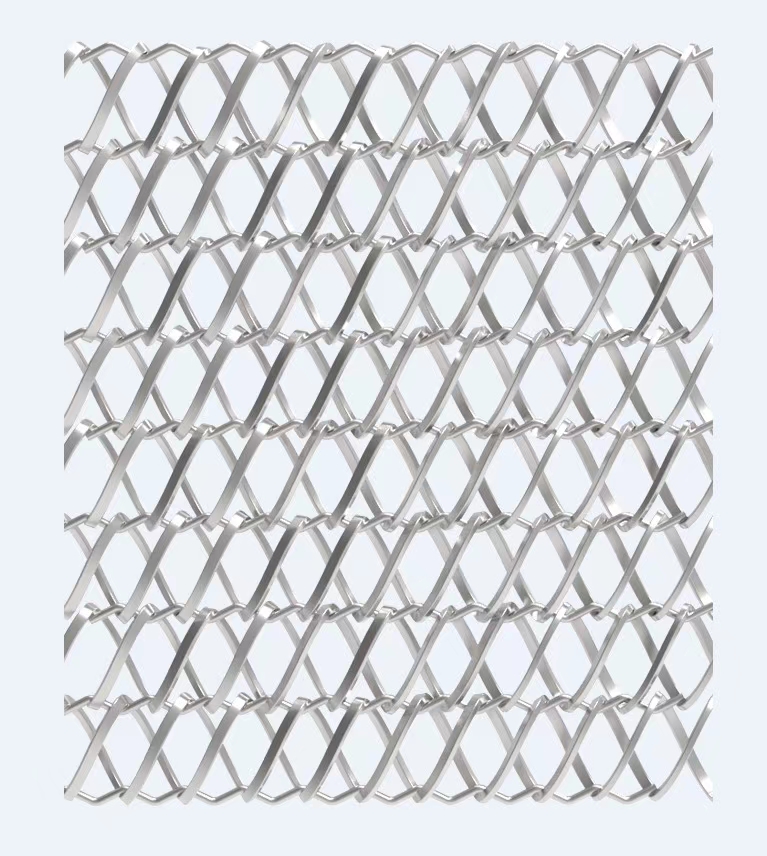

Double wire Dutch weave: This weave is very similar to the twill Dutch weave. There are two weft threads that can overlap closely with the warp threads. This kind of silk cloth is mostly used for micron level filtration.

Five-harness braiding is a kind of braiding in which the warp and weft threads are not made of single filaments but several separate filaments. This weave is based on twill weave to provide a stronger and more powerful stainless steel wire cloth.

Contrast weave: The difference in appearance is that compared with the standard weave method, more bent wires and less weft wires are used. The weft threads of the contrast weave are much thicker than the warp threads.

Uses of stainless steel wire mesh:

1. Used for screening and filtration under acid and alkali environmental conditions.

2. Used as mud mesh in the petroleum industry, screen mesh in the chemical fiber industry, and pickling mesh in the electroplating industry.

3. Used in industry and construction to screen sand and filter liquids and gases.

4. Paper making and printing industry.

Post time: Mar-05-2024