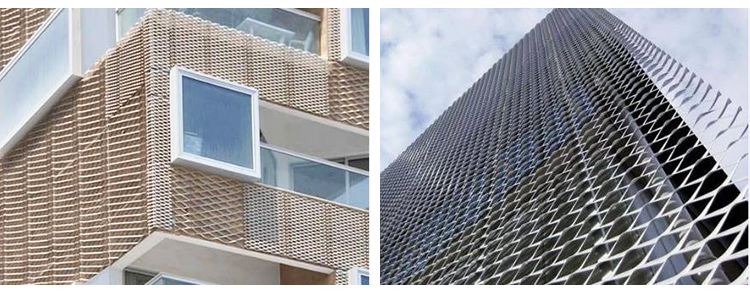

As an important form of modern building exterior wall decoration, steel mesh curtain wall is favored by more and more architects and developers because of its unique visual effect, good permeability and excellent structural performance. This article will explore the manufacturing process of steel mesh curtain wall in depth, from material selection, production process to quality control, and fully reveal the birth process of this architectural element.

1. Material selection

The main material of steel mesh curtain wall is steel plate, and the choice of steel plate directly determines the performance and life of the curtain wall. High-quality steel plate should have good corrosion resistance, sufficient strength and good processing performance. Common steel plate materials include stainless steel, galvanized steel and weathering steel. Stainless steel has become the first choice for high-end curtain walls due to its excellent corrosion resistance; galvanized steel improves rust resistance through surface zinc coating and is suitable for a variety of environments; weathering steel is often used for outdoor landscape curtain walls due to its unique atmospheric corrosion resistance.

When selecting steel plates, you also need to consider their thickness, specifications and surface treatment methods. The thickness directly affects the strength and stability of the curtain wall, while the specifications need to be customized according to the architectural design requirements. Surface treatment methods such as pickling, polishing, spraying, etc. can further improve the beauty and weather resistance of the steel plate.

2. Production process

The production process of steel plate curtain wall mainly includes steel plate cutting, mesh processing, bending forming, welding assembly and surface treatment.

Steel plate cutting: According to the design drawings, use high-precision cutting equipment (such as laser cutting machine, plasma cutting machine, etc.) to accurately cut the steel plate. The cutting speed and temperature must be strictly controlled during the cutting process to avoid the influence of the heat-affected zone on the performance of the steel plate.

Mesh processing: Uniform mesh is formed on the steel plate by stamping or weaving. The shape, size and distribution of the mesh need to be customized according to the design requirements. This step requires high precision and stability of the production equipment.

Bending forming: Use professional bending equipment to bend the steel plate into the required surface or angle. The bending accuracy and surface quality must be ensured during the bending process to ensure the overall beauty and structural stability of the curtain wall.

Welding assembly: Weld and assemble the cut and processed steel plate components. During welding, the welding current, voltage and welding speed must be strictly controlled to ensure the quality and strength of the weld. At the same time, the weld needs to be polished and rust-proofed.

Surface treatment: According to the design requirements, the curtain wall is sprayed, brushed or polished. Surface treatment can not only improve the aesthetics of the curtain wall, but also enhance its weather resistance and corrosion resistance.

3. Quality control

In the manufacturing process of steel mesh curtain wall, quality control is crucial. From the entry of raw materials to the exit of finished products, each process requires strict quality inspection.

Raw material inspection: The thickness, chemical composition, surface quality and other aspects of the steel plates entering the factory are inspected to ensure that the raw materials meet the design requirements.

Process inspection: During the production process, the cutting, processing, bending, welding and surface treatment links are inspected in real time to find and correct problems in time.

Finished product inspection: The finished product is comprehensively inspected in terms of appearance quality, dimensional accuracy, structural stability and other aspects. At the same time, performance tests such as tensile strength, yield strength, corrosion resistance, etc. are also required to ensure that the finished product meets the relevant standards and design requirements.

Post time: Feb-17-2025