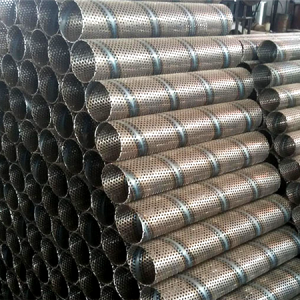

Perforated tube, also name perforated pipe, punching pipe. Perforated tube is made of stainless steel punching plate by welding. It has the characteristics of uniform pipe diameter, firm weld and strong flexibility. The manufacturing process is CNC punching shearing bending welding.

Perforated tube can be divided into two welding methods: straight seam welding and spiral welding. Straight seam welding is named after the straight line of the welding part of the network management. Spiral welding is to bend the punched plate and strip according to the spiral shape for argon arc welding. Punching network management is a kind of extended product of punching network plate. The hole shape is round hole, square hole, long hole and diamond hole.

Widely used in oil production, chemical industry, sewage treatment, purified water treatment equipment, interior decoration, etc; Spiral welded punching pipe can also be used as the framework of filter element, with large supporting force, high roundness and good straightness. Dongjie can make customization according to customer requirements.

Type 1: Straight seam welded punched pipe

Pipe punching refers to the processing of pipes to meet different needs, such as plum blossom hole, hexagon hole, long hole, square hole, round hole, triangle hole, etc.

Stainless steel pipe, perforated pipe. Perforated spiral welded filter pipe is widely used in automobile muffler, automobile and motorcycle exhaust pipe; Oil production, chemical industry, sewage treatment, purified water treatment equipment, can be used for oil sand pipe, also can be used as filter framework.

Type 2: Galvanized piercing spiral pipe/Carbon steel piercing spiral pipe

Spiral pipe, also known as spiral steel pipe or spiral welded pipe, is made by rolling low carbon structural steel or low alloy structural steel strip into tube blank according to a certain helix angle (called forming angle), and then welding the pipe seam. It can produce large diameter steel pipe with narrow strip.

Perforated Tube production process:

1. According to the customer's requirements, the width of the strip is designed for punching and slitting.

2. After perforation, the mesh belt is coiled in a spiral or straight shape (punching face inward or outward) for argon arc welding.

3. The advantages of perforated pipe produced by our factory are: uniform weld, strong compression capacity, standard roundness and good straightness.

4. Widely used in: muffler, oil production, chemical industry, sewage treatment, purified water treatment, water filtration, various filter element framework, filter components, etc.

Post time: Jun-11-2021