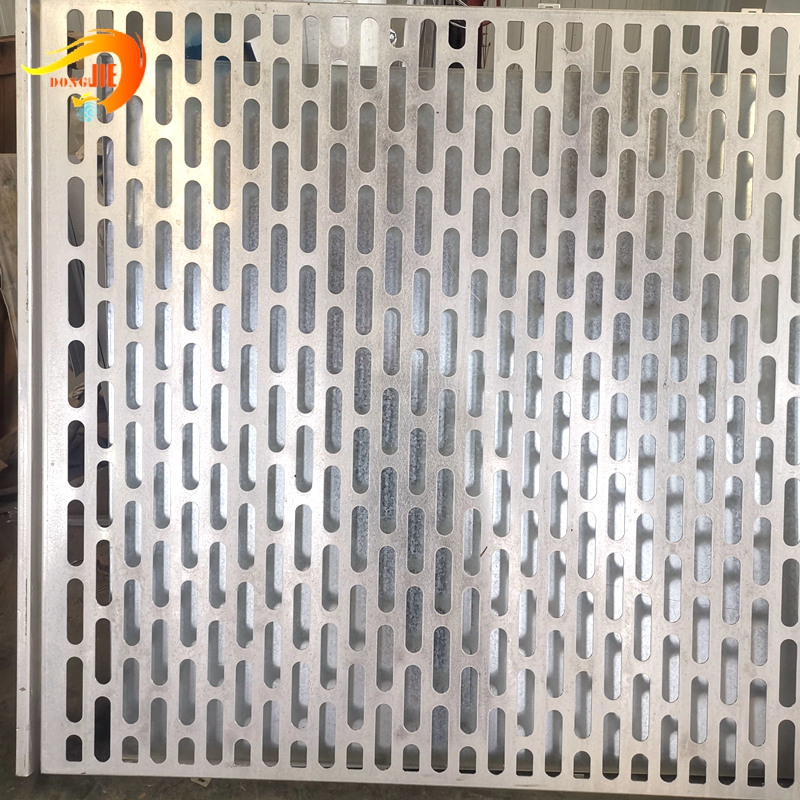

Long-hole stainless steel punching mesh refers to a punching plate with a hole shape of rectangular holes or oblong holes and a stainless steel plate as the raw material. Mainly used for solid filtration, mainly used in vibrating screens. The specific aperture and pattern size are subject to customer requirements.

There are many materials for stainless steel plates. Commonly used ones include: 201 stainless steel plates, 304 stainless steel plates, 316 stainless steel plates, 316L stainless steel plates, etc. 201 is actually what people commonly call stainless steel; 304 is the most widely used material among stainless steel plates; the difference between 316 and 316L stainless steel plates is the carbon content and nickel content. The carbon content of 316 stainless steel plate is ≤0.08, and the nickel content is 10-14; the carbon content of 316L stainless steel plate is ≤0.03, and the nickel content is 12-15; and the carbon content of 321 stainless steel plate is ≤0.08, and the nickel content is 9 -13. (The most common ones are 304 stainless steel punching plates and 316 stainless steel punching plates)

The unique advantages of long hole stainless steel punching mesh are:

1. Corrosion-resistant, non-flammable, non-toxic and tasteless.

2. Good wear resistance and long service life. The wear resistance of stainless steel punching mesh is 3 to 5 times that of ordinary sieve plates and more than 5 times that of ordinary rubber sieve plates.

3. The total cost is low. Although the one-time investment of stainless steel punching plates of the same specification (area) is higher than that of ordinary screen plates (about 2 times), the service life of stainless steel punching plates is 3 to 5 times that of ordinary screen plates, and maintenance is And the number of replacements is small, so the total cost is not high and it is economically very cost-effective.

Stainless steel punching mesh is lightweight and non-slip

Stainless steel punching mesh raw material: stainless steel plate.

Post time: Feb-01-2024