Plastic spray punching mesh, spray molding punching plate mesh, Hebei Anping County Dongjie Wire Mesh Products Co., Ltd. provides you with it!

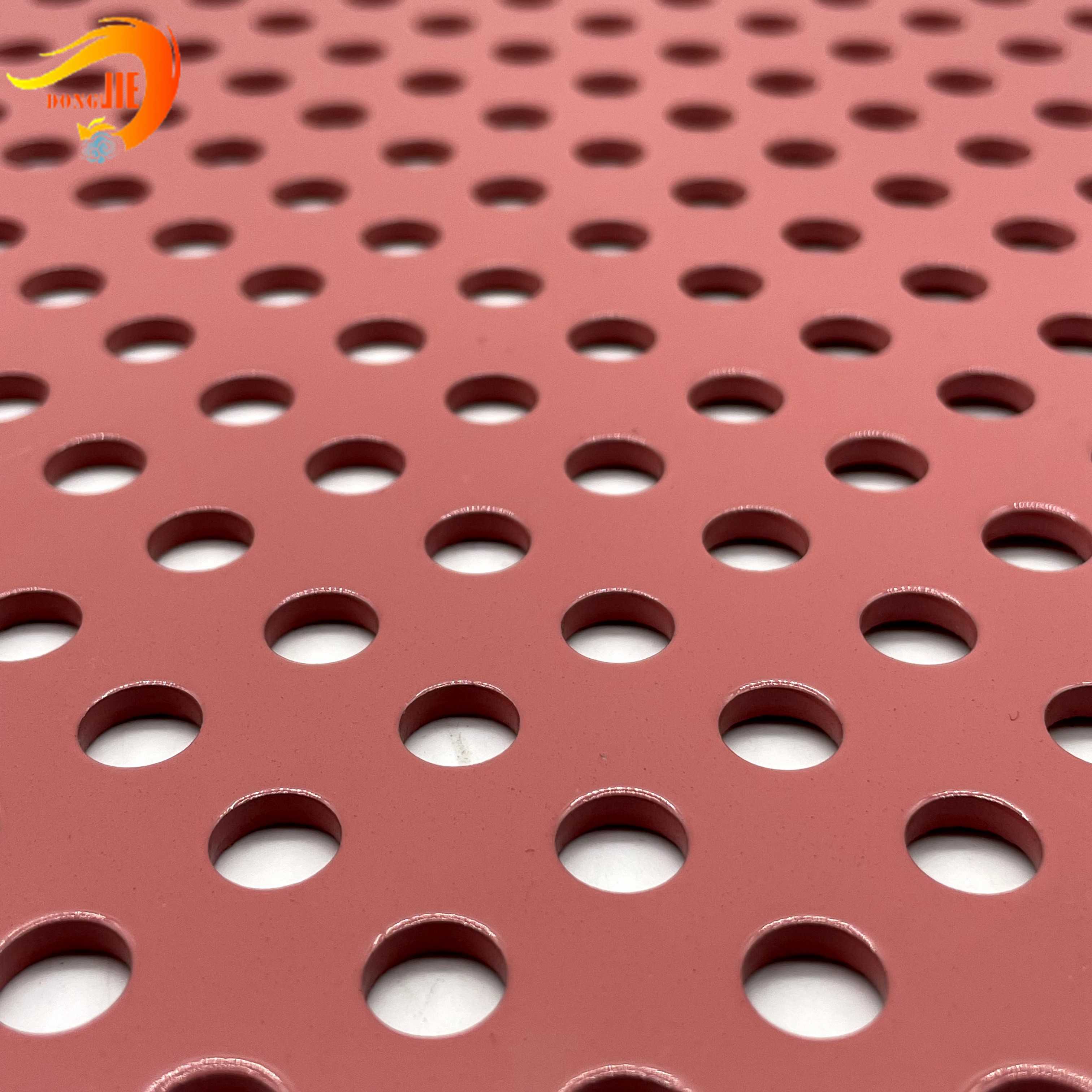

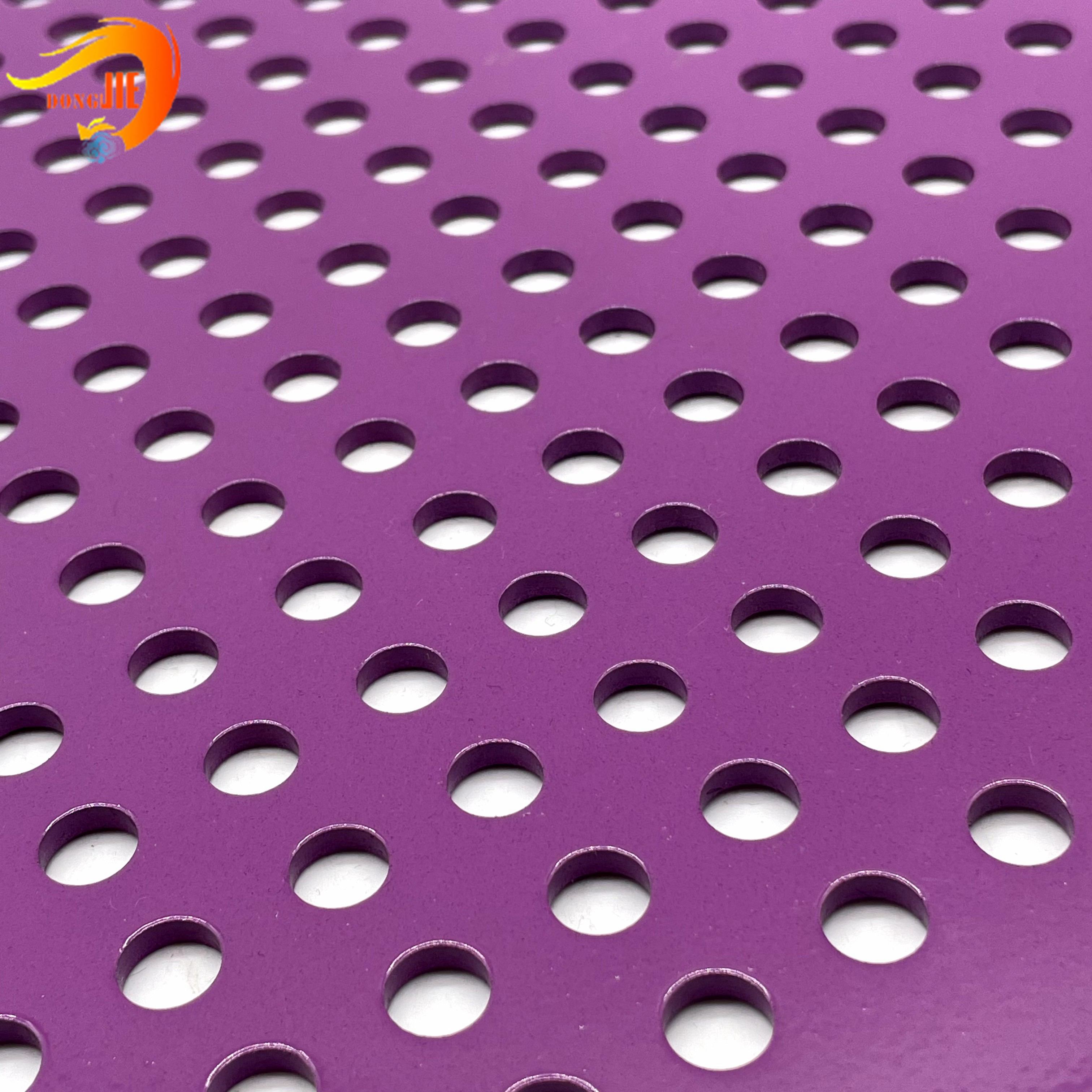

Most of the materials used in perforated mesh are metal, and the color is naturally metal. However, many times, due to some special needs, such as house decoration, handicraft production, etc., punching mesh products need to have beautiful colors. This wish can be realized using the spray molding process.

Plastic spraying is a relatively complex chemical reaction process. It uses electrostatic powder spraying equipment to spray plastic powder coating onto the surface of the perforated mesh. Under the action of static electricity, the powder will be evenly adsorbed on the surface of the perforated mesh to form a powder coating; The powder coating is baked at high temperature to plasticize and then solidify. Finally, a plastic layer is formed on the surface of the punching mesh that has both anti-corrosion and aesthetic effects.

Plastic spray punching mesh generally uses stainless steel plates, aluminum plates, and cold-rolled plates. After CNC machining and drilling, various beautiful hole shapes are made, and then cut and bent into shape. Finally, spray plastic surface treatment is performed, and it is processed into Various bright colors: white, blue, green, gray and more.

Types of metals that microporous round hole mesh can process: various metals, alloys and stainless steel plates and strips; plate thickness range: thin plates of 2mm and below, especially suitable for thin plates of 0.5mm and below;

Industry use:

(1) Precision filters, filter plates, filter cartridges, and filters for petroleum, chemical, food, and pharmaceutical industries;

(2) Metal drain plates, cover plates, flat pins, lead frames, and metal substrates used in the electronics industry;

(3) Precision optical and mechanical flat parts and spring parts;

(4) Friction plates and other concave and convex flat parts;

(5) Metal dials, metal decorative plates with complex patterns and exquisite handicrafts.

Post time: Nov-13-2023