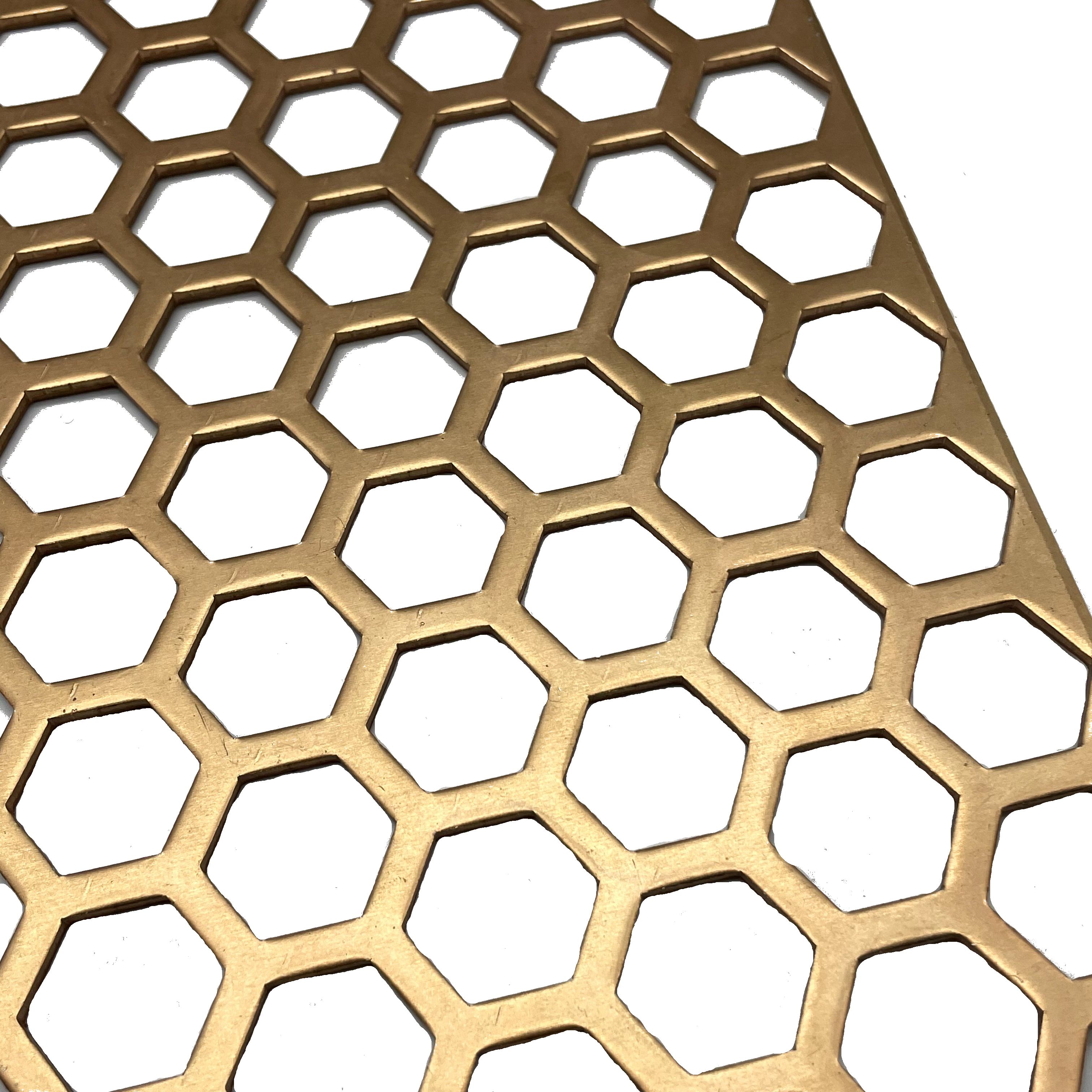

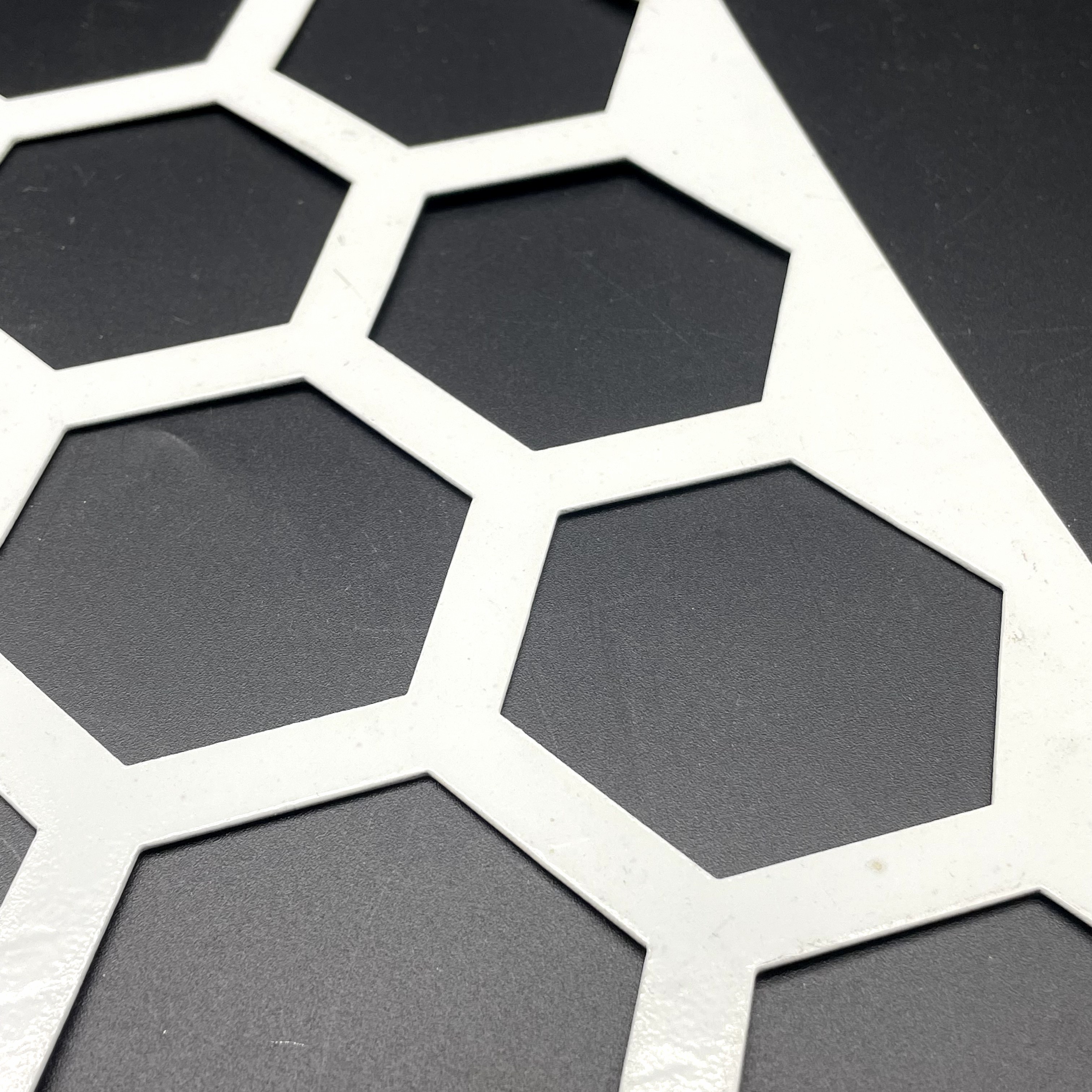

Introduction to Hexagonal Hole Perforated Mesh

Hexagonal hole perforated mesh is a kind of hole punched in a certain range on plates of various materials. The punched hole type is hexagonal hole, hence the name hexagonal hole perforated mesh. Common materials of this mesh include low-carbon plate, stainless steel plate, copper plate, aluminum plate, nickel plate, galvanized plate, etc.

Specifications and dimensions

The specifications and dimensions of hexagonal hole perforated mesh are diverse, including the thickness of the plate and the size of the hole diameter, as well as the size of the perforated plate. For example, the plate thickness can be 0.8mm, 1.0mm, 1.5mm, 2.0mm, etc., the hole diameter can be 5.0mm, 6.0mm, 8.0mm, 10mm, etc., and the size of the perforated plate can be 1000x 2000mm, 1220x 2440mm, 1250x 2500mm, etc.

Anti-corrosion treatment

Hexagonal hole perforated mesh can also be subjected to surface anti-corrosion treatment such as galvanizing, painting, and plastic spraying. The treated color is bright, the corrosion resistance is strong, and it is easy to clean, thereby extending the service life.

Application range

Hexagonal hole punching mesh has a wide range of applications, including exterior wall decorative panels, indoor partition panels, outdoor shielding panels, and indoor ceilings. Specifically, it can be used for decorative mesh panels in shopping malls, car shops and other places, and can also be used as indoor partition panels in office buildings, shopping malls, and workshops, or for factory site enclosures, farm enclosures, and housing enclosures to block pedestrian sight. In addition, it can also be used in hotels, administrative halls and other places. Ceilings.

In general, hexagonal hole punching mesh is widely used in various fields due to its unique hexagonal hole shape and various specifications and sizes, meeting different usage needs.

Post time: May-08-2024