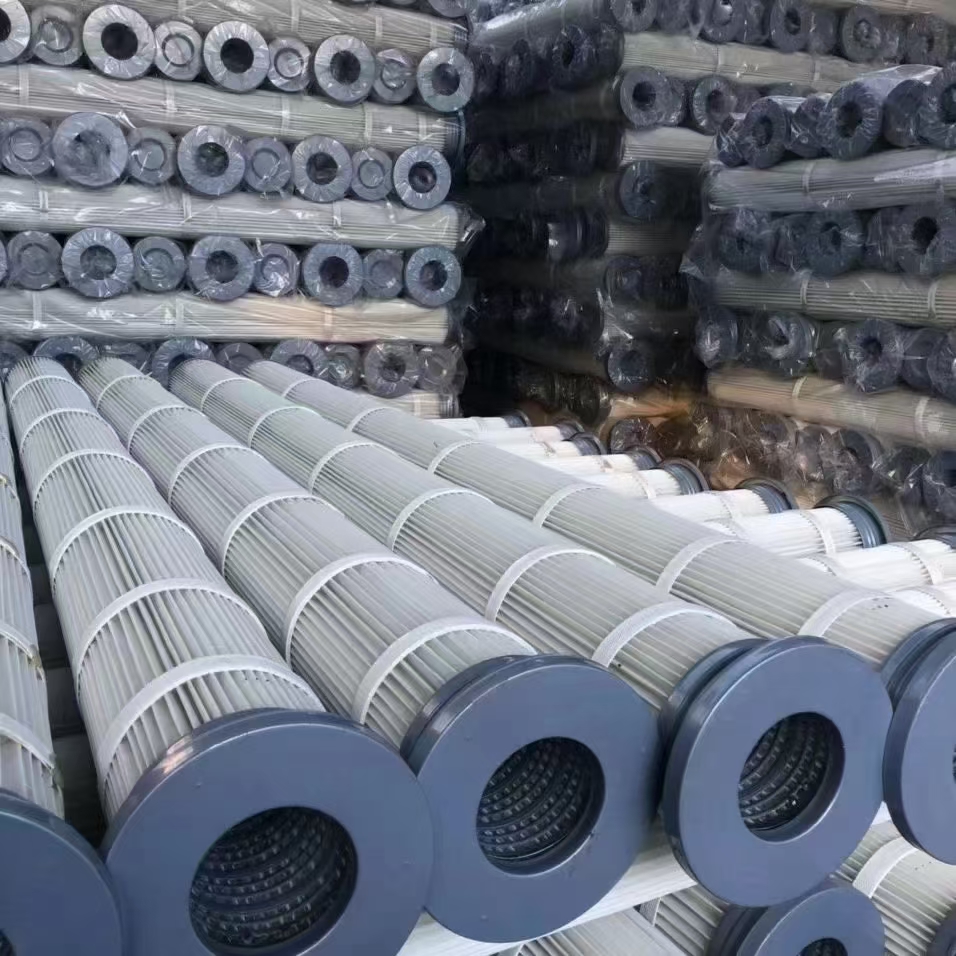

In the fields of ventilation and dust removal, large machinery filtration and other fields, the dust filter cartridge is an indispensable dust-proof device. Because of its advantages of acid and alkali resistance, corrosion resistance, high temperature resistance, high pulling force, high strength, low running resistance, large air volume, large filtration area, and high filtration efficiency, it has won the favor of various industries.

The dust filter cartridge is a device used to filter particles and pollutants in the air. It consists of the following parts:

1. Cylinder body: usually made of metal or plastic, with certain strength and corrosion resistance.

2. Filter media: usually made of fiber materials, ceramics, metal mesh and other materials, used to filter particles and pollutants in the air.

3. Support net: used to support the filter medium to ensure that it does not deform or collapse during use.

4. Seals (filter end caps): used to connect the cylinder and other components to ensure the filtration effect.

Cleaning of dust filter cartridge

Commonly used automatic cleaning methods for dust removal cartridges include high-pressure gas pulse backflushing, mechanical vibration pulse backflushing, which uses the preset parameters of the controller to give a signal to the solenoid valve, which instantly opens and closes the solenoid valve diaphragm to press the gas into the blow pipe. The rapid expansion force of the gas is used to shake off the dust on the surface of the filter cartridge. Generally, the gas pressure is set to about 6 kilograms of force. Mechanical vibration cleaning is often used in small stand-alone filter cartridge dust collectors. It is generated by the eccentric device on the dust collector panel. The shaking force is used to clean the dust. This action requires shutting down the machine and operating the cartridge filter.

Production Process:

1. Cylinder processing: According to the design requirements, metal or plastic materials are processed into the shape of the cylinder.

2. Preparation of filter media: Select appropriate materials according to requirements and prepare filter media of certain specifications.

3. Preparation of support net: Select appropriate materials according to requirements and prepare support nets of certain specifications.

4. Cylinder assembly: Place the filter media and support net into the cylinder, and use seals to connect the cylinder with other components.

5. Inspection and testing: Inspect and test the assembled dust filter cartridge to ensure that it meets the design requirements and usage requirements.

6. Packaging before leaving the factory: Qualified dust filter cartridges are packed before leaving the factory.

This dust removal filter cartridge has the advantages of simple structure, convenient operation, high processing efficiency, and wide application range. It is widely used in steel, cement, chemical industry, electric power, mining and other industries. At the same time, dust removal filter cartridges also need to be designed and selected according to different working conditions and dust characteristics to achieve the best dust removal effect.

Post time: Mar-07-2024