As a kind of decorative mesh, crimped mesh is widely used in today's society. Crimped mesh can be seen in daily life and in industry. Next, I will give you a detailed introduction to crimped mesh. This includes the production process and specific uses of crimped mesh.

(Crimped wire mesh is widely used in today’s society. All walks of life can basically come into contact with crimped wire mesh. There are many advantages of crimped wire mesh. Next, Anping Dongjie will introduce to you the production process of crimped wire mesh and the process of crimped wire mesh. Please listen to me explain to you the purpose of the flower net.)

Crimped mesh has different names according to different classification methods;

Depending on the material, it can be called wire crimped mesh, galvanized crimped mesh, white steel crimped mesh, black steel crimped mesh, stainless steel crimped mesh, wire rod crimped mesh, copper-clad steel crimped mesh.

Depending on the use, the crimped mesh can also be used as a mine screen crimped mesh, pig raising crimped mesh, barbecue crimped mesh, granary crimped mesh, or decorative crimped mesh.

According to the shape, it can also be called knotted crimped mesh, edge-wrapped crimped mesh, and crimped mesh.

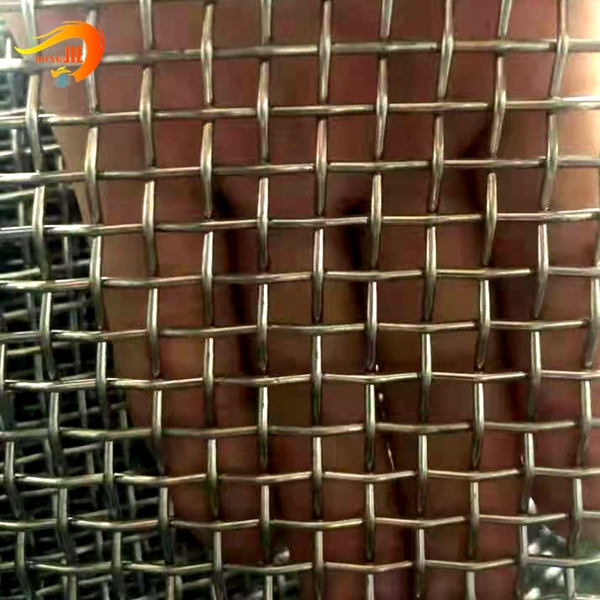

The crimped mesh is a square mesh made by weaving metal wires of different materials and specifications through a crimping machine and then a new mesh weaving machine. It is a wire mesh product with multiple uses.

Production Process

The crimped mesh adopts the weaving method of first pressing and bending and then forming, including: two-way wave-isolating bending, flat-top bending, two-way bending, locking bending, and rolling first and then braiding.

Material: 201, 302, 304, 304L, 304A, 316, 316L, 321, 310S and other stainless steel wires

Advantages of crimped mesh products

1. High smoothness, no surface treatment required, easy and simple maintenance.

2. Resistant to high temperature oxidation, the 304 stainless steel screen has a temperature resistance of 800 degrees Celsius.

3. Good acid resistance, alkali resistance and corrosion resistance;

4. High strength, strong tensile strength, toughness and wear resistance, and durable.

Product Usage

It is used for screening and filtration under acid and alkali environmental conditions. It is used as a mud mesh in the petroleum industry, as a screening mesh in the chemical and chemical fiber industry, as a pickling mesh in the electroplating industry, in wastewater treatment, and in paint and metal powder manufacturing. Used for solid particles, powders, sieving, etc. in aerospace, printing and dyeing, electronics, minerals, pharmaceuticals, grain, food processing, metallurgy, ceramics, glass and other industries.

Post time: Mar-01-2024