Expanded metal mesh is a wire mesh product with stretched metal sheets. It has uniform holes, firm nodes, non-slip, wear-resistant, strong tensile strength, strong mesh surface, and easy maintenance. It is widely used in many fields of production and life.

So if you want to produce high-quality expanded metal mesh products, you need to pay attention to several aspects:

1. Material selection: expanded metal mesh is formed by punching and stretching steel plates, so when selecting plates, it is necessary to use softer 195L material;

2. Kaiping: The raw material belongs to the coiled plate and needs to be cut by Kaiping to the corresponding size before production, so choose a sheet with a relatively flat mesh surface, and the surface must not be distorted and deformed;

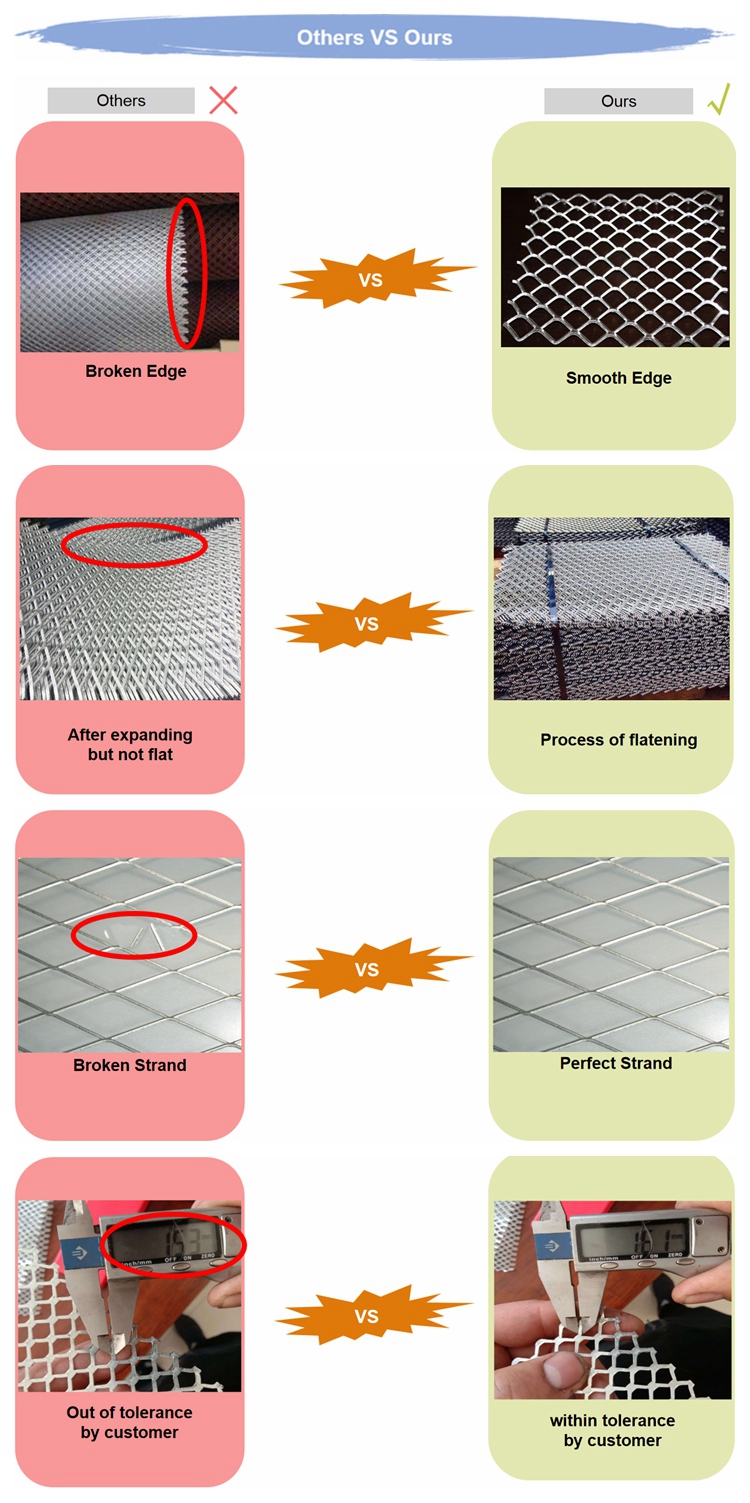

3. Debugging: In the production process of expanded metal mesh, the debugging of the machine is the key. The machine tool needs to be polished in place to avoid burrs, and the numerical control needs to be debugged in place to avoid broken stems, large and small stems, and mesh surface distortion;

4. Inspection: After the commissioning is completed, it is necessary to continuously measure the size of the steel mesh stem wire and the length of the mesh surface during mass production. According to the required data, the debugging is in place, and the interval of several hours requires continuous spot checks and measurements. If problems are found, they need to be adjusted in time. ;

5. Finished product: placed neatly, the rolls need to be rolled up neatly, if placed and the whole roll is not neat, it is easy to be damaged during transportation.

6. Packaging: Generally, steel expanded metal sheets and rolls are not packaged; the cost of aluminum expanded metal and stainless steel expanded metal is relatively high. In order to avoid wear and tear during transportation, it is recommended to choose pallets + packaging materials for double protection. It can not only avoid crushing, but also be dustproof and waterproof.

The above are the main points of quality control in the production process of expanded metal mesh. Every responsible expanded metal mesh factory strictly controls these aspects. Of course, there are also some irresponsible factories that, in order to save costs, choose inferior plates and fail to strictly control the production process, resulting in a decline in product qualification rates and losses to customers.

Anping Dongjie Wire Mesh Factory has specialized in the production of expanded metal mesh for 26 years, has rich production experience, and strictly controls every link to ensure the production of products that satisfy customers.

If you have relevant needs, welcome to contact us.

If you need it, just click the button below.

Post time: Jan-29-2023