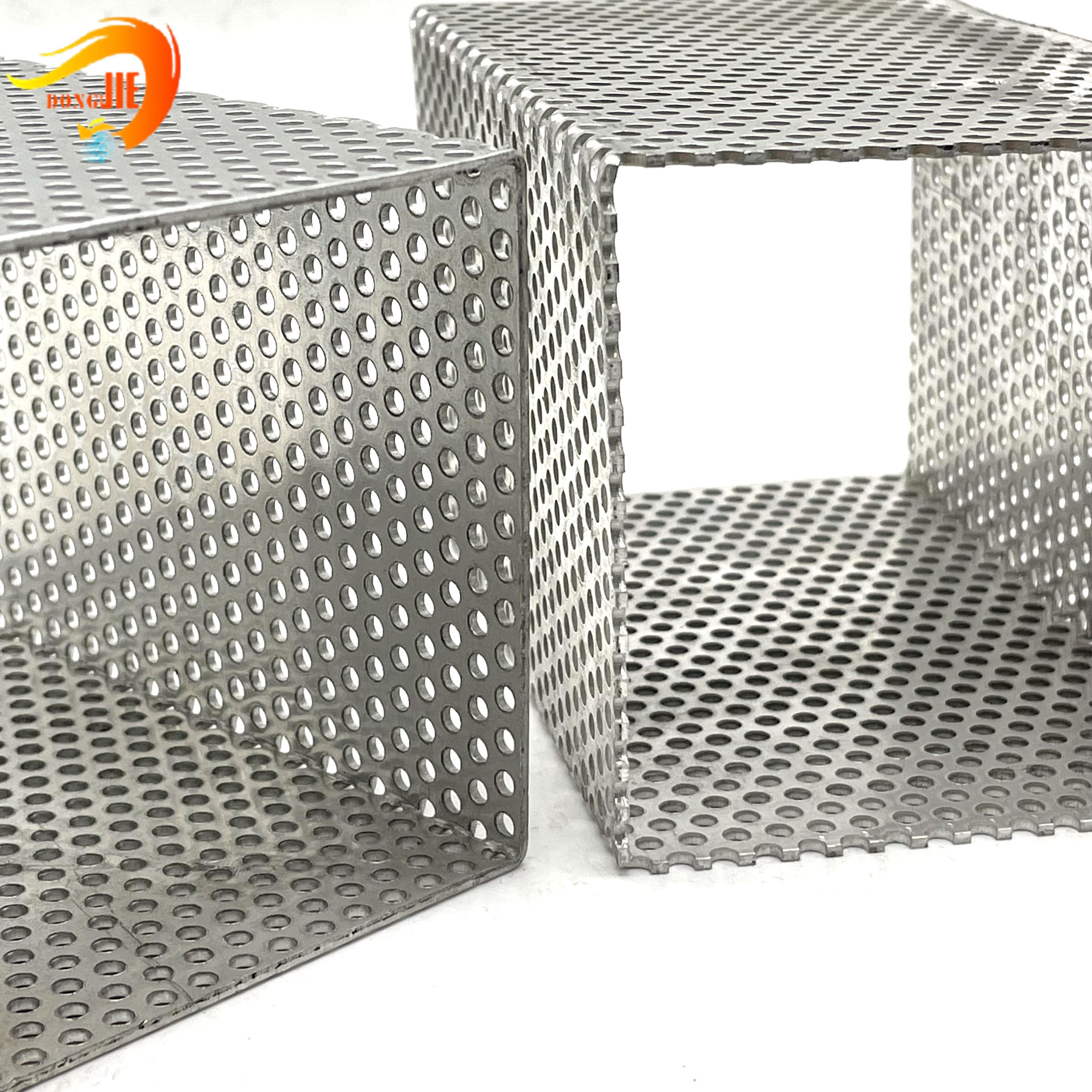

Piercing metal filter cartridge is a common filter element, usually composed of a perforated plate and a cylindrical structure. It has a wide range of characteristics and applications. The following is a detailed introduction to the perforated metal filter cartridge:

1. Materials and structure

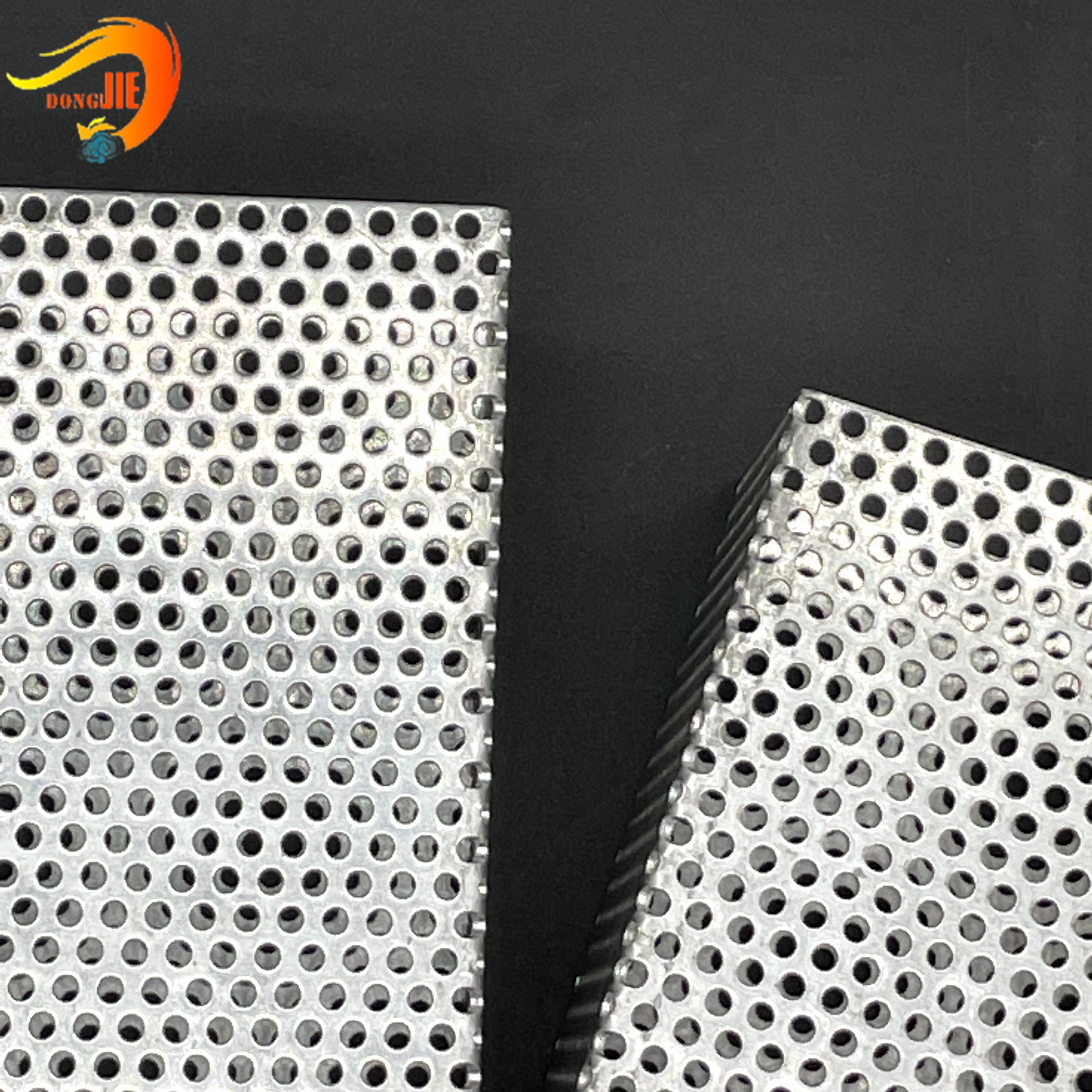

Material: Perforated metal filter cartridges are generally made of galvanized sheet or stainless steel perforated mesh as raw materials. Stainless steel is the preferred material for making high-quality filter cartridges due to its excellent corrosion resistance and mechanical properties.

Structure: The perforated plate part of the filter cartridge has many small holes, which are used to block or capture solid particles while allowing liquid or gas to pass through. The cylindrical structure provides stable support and filtration area.

2. Features

Excellent filtration performance: The perforated metal filter cartridge has outstanding filtration performance for particles and liquids of 1-500um, and can effectively remove impurities.

Good air permeability: Due to the small hole design of the perforated plate, the filter cartridge has good air permeability, which is conducive to the smooth passage of gas or liquid.

Simple process: The manufacturing process of the perforated metal filter cartridge is relatively simple and the production cost is low.

Good regeneration performance: It can be reused after cleaning, extending the service life.

Convenient installation: The design of the filter cartridge makes installation and removal simple and quick.

3. Uses

The uses of perforated metal filter cartridges are very wide, mainly including but not limited to the following aspects:

Industrial fields:

Petrochemical industry: used for filtering high-temperature gases, corrosive liquids, and catalysts.

Metallurgical industry: used for purification of high-temperature flue gas.

Pharmaceutical industry: used for filtering and separating catalysts.

Chemical fiber film industry: used for filtering and purifying polymer solutions.

Environmental protection field:

Air purification: used in air conditioners, purifiers, range hoods, air filters and other equipment to remove dust and pollutants in the air.

Water treatment: used to purify and filter production wastewater and protect water resources.

Other fields:

Food industry: used to filter edible oils, beverages and various edible slurries to ensure food safety and hygiene.

Gas distribution: used for liquidized bed orifice materials to achieve uniform distribution of gas.

4. Purchase suggestions

When purchasing perforated metal filter cartridges, the following factors need to be considered:

Material: Choose stainless steel with corrosion resistance and good mechanical properties.

Aperture: Choose the appropriate aperture size according to the filtration requirements.

Structure: Ensure that the structure of the filter cartridge is stable and can withstand the working pressure.

Brand and manufacturer: Choose a brand and manufacturer with good reputation and rich production experience to ensure product quality and after-sales service.

In summary, the perforated metal filter cartridge plays an important role in industrial production, environmental protection and other aspects with its superior filtering performance, good air permeability and wide application fields.

Post time: Aug-13-2024