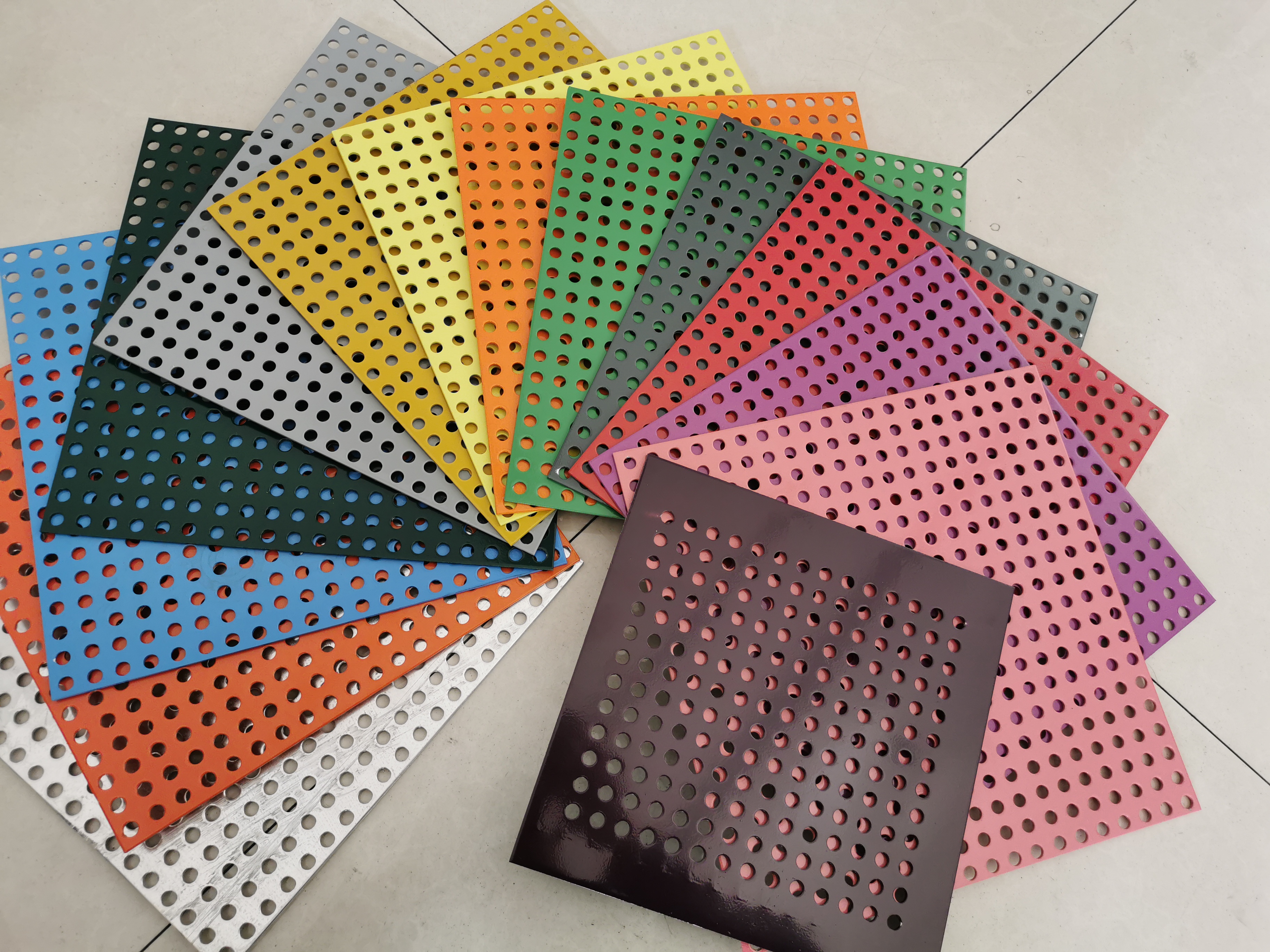

Nowadays, metal perforated mesh is used in many applications in life. Since it is a metal product, it is also a consumable. As the service life increases, the metal perforated mesh will be damaged one day. Stainless steel perforated mesh can be used as sound-absorbing materials for building ceilings and wall panels; it can be used as exquisite decorative perforated plates for building stairs, balconies, and environmentally friendly tables and chairs; it can be used as protective covers for mechanical equipment, gorgeous speaker grilles, food, Grinding sieves, ore sieves, I-shaped sieves for feed and mining, stainless steel fruit baskets, food covers, fruit plates and other kitchen utensils for kitchen equipment, as well as shelf nets for shopping malls, decorative exhibition stands, ventilation nets for grain depots, football Lawn seepage filter. Anti-corrosion; stainless steel perforated mesh is corrosion-resistant (316L stainless steel perforated mesh is particularly outstanding), non-flammable, non-toxic and tasteless.

Stainless steel punching mesh types are rectangular holes, square holes, diamond holes, round holes, hexagonal holes, cross holes, triangular holes, oblong holes, long waist holes, plum blossom holes, fish scale holes, pattern holes, and five-pointed star holes. , irregular holes, drum holes, etc. Anti-skid plates for oilfield drilling platforms are rubber-metal hybrid anti-skid plates. Compared with traditional single-metal anti-skid plates, they are more suitable for the working surface of oilfield drilling platforms. Scattered mud on the drill floor can flow away through the joints between blocks, ensuring that the drill floor is clean and tidy. It enhances the safety of workers on the playground, improves the anti-slip ability, and facilitates laying and disassembly. Long life: good wear resistance and long service life. The wear resistance of stainless steel punching mesh is 3 to 5 times that of ordinary metal punching mesh, and more than 5 times that of ordinary rubber screen plates.

Stainless steel perforated mesh is also widely used in the electronics industry, such as audio dust-proof soundproof covers, etc. Stainless steel perforated mesh is easy to process and shape, can be painted or polished, easy to install, eye-catching appearance, various thicknesses of plates, various Selected hole diameter and arrangement · Good sound absorption · Light weight · Long service life · Precise dimensions. Low total cost: Although the cost of stainless steel punching mesh of the same standard is higher than that of ordinary punching plates, the use time of stainless steel punching plates is 3 to 5 times that of ordinary punching plates, and the number of repairs and replacements is less, so The total cost is not high and it is economically very cost-effective.

Post time: Nov-07-2023