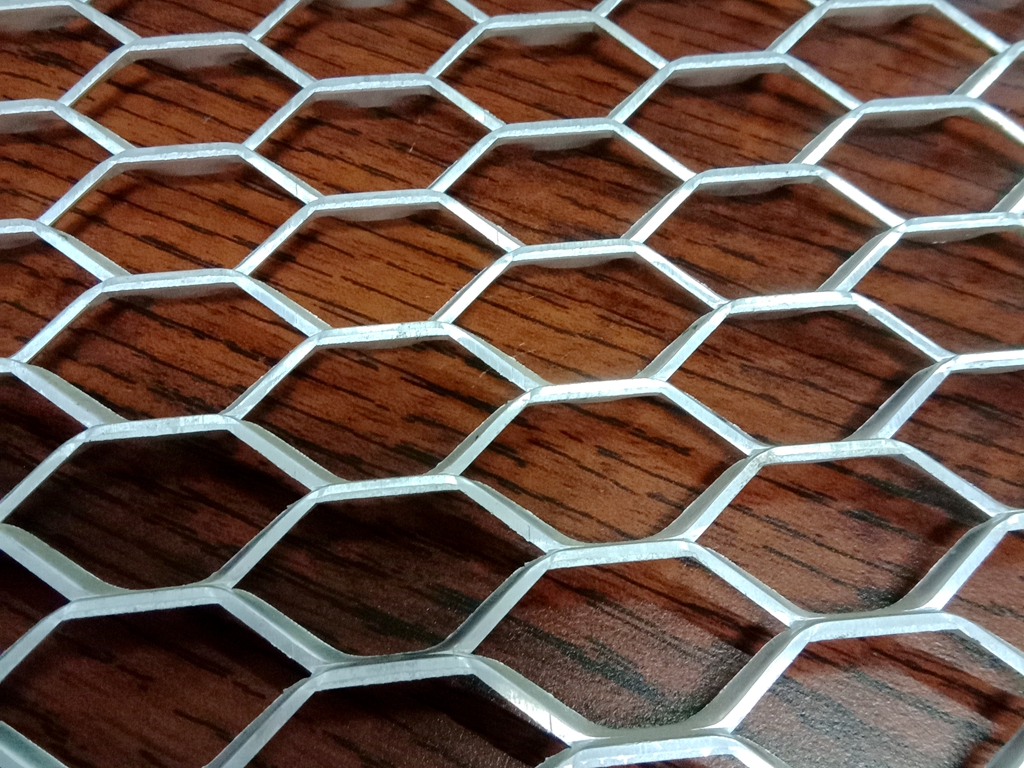

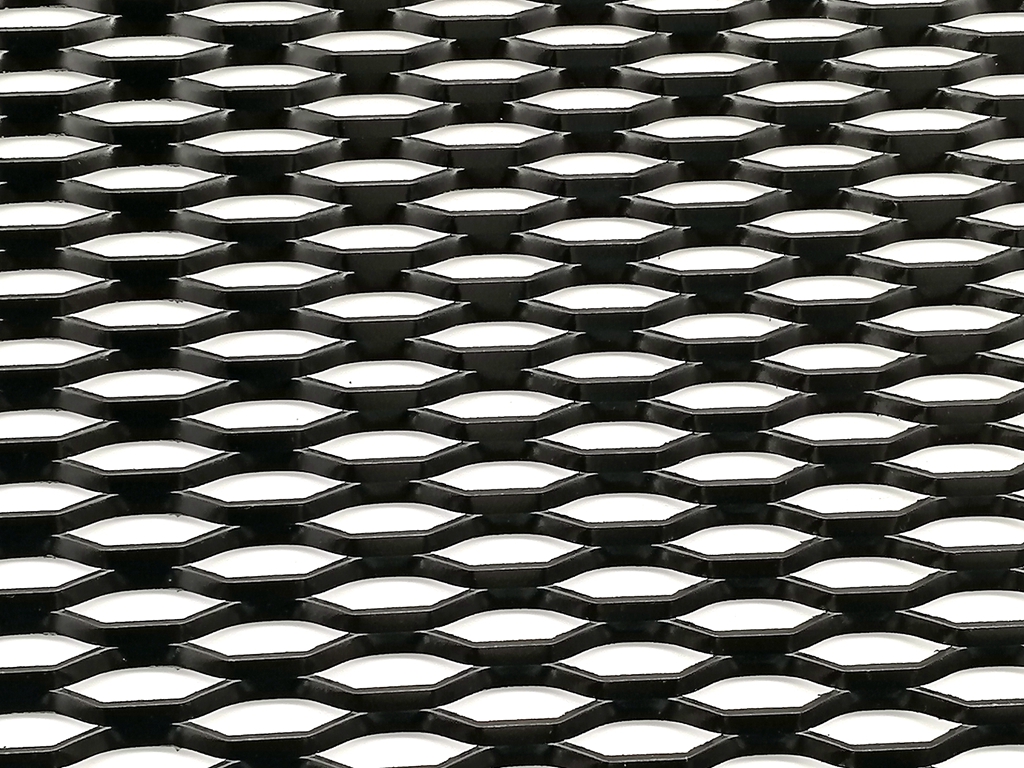

Bolong logam sing ditambahi heksagonal uga dikenal minangka bolong baja berbentuk kura-kura, bolong baja batang sing padha, lan bolong baja pola isosceles.Hexagonal ditambahi bolong logam kawangun dening punching lan drawing karo piring baja kualitas dhuwur.Lumahing diolah kanthi lukisan lan galvanizing.Wis werna padhang, ora teyeng, lan awet.

Bolong logam sing ditambahi heksagonal ngalami owah-owahan saka cetakan produksi berlian sing ditambahi bolong logam, dadi bolong logam sing ditambahi heksagonal nduweni sifat bolong logam sing ditambahi berlian.Ing wektu sing padha, amarga amba gedhe antarane pinggiran kepekso lan pinggiran sakcara saka Hexagonal ditambahi bolong logam, piring logam karo kateguhan kuwat dipilih ing produksi Hexagonal ditambahi bolong logam.Nanging, amarga struktur fisik sing unik, bolong logam sing ditambahi heksagonal ora mung nduweni sifat bolong logam sing ditambahi berlian nanging uga nduweni karakteristik ketangguhan sing dhuwur, resistensi impact sing kuat, struktur sing kuwat, penampilan sing ayu, lan liya-liyane.

Ing proses produksi bolong logam sing ditambahi heksagonal, piring logam kanthi kateguhan sing kuat kudu dipilih kanggo produksi.Nanging, amarga struktur fisik unik, bolong logam ditambahi heksagonal nduweni kaluwihan saka kateguhan gedhe lan resistance impact kuwat, lan struktur bolong logam ditambahi heksagonal banget kuwat, lan katon bolong logam ditambahi heksagonal uga ayu banget.Mulane, bolong logam sing ditambahi heksagonal banget populer.

Bahan: Plat baja karbon sing angel, piring aluminium, piring stainless steel, piring alloy aluminium-magnesium, piring tembaga, piring nikel lan piring liyane sing dibutuhake pelanggan.

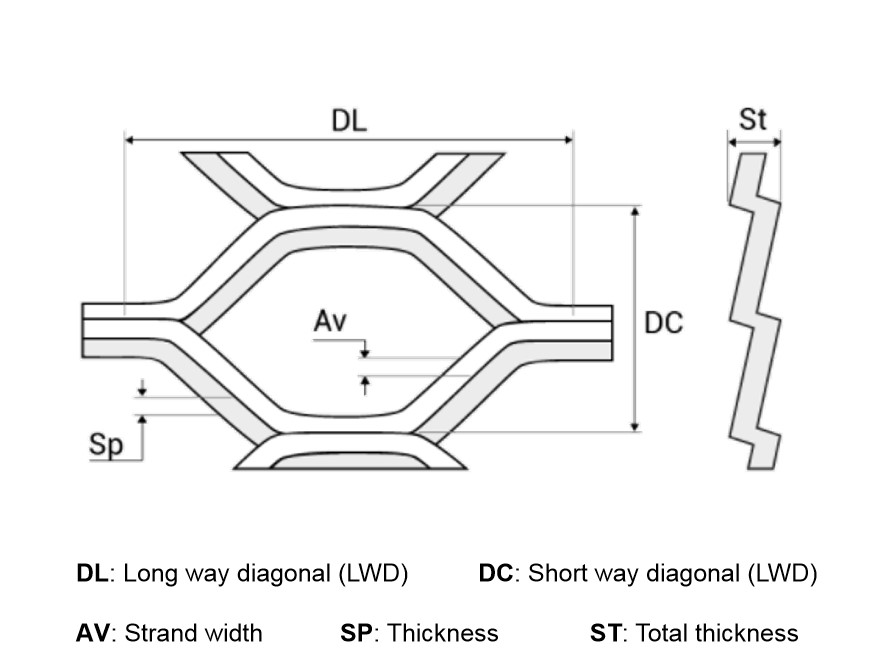

Spesifikasi: Kekandelan saka piring: 0.8mm-6mm, cara cendhak mbukak: 10-60mm, dawa mbukak 2-120mm.Lebar lan dawa piring kasebut miturut syarat pelanggan.

Gunakake: Hexagonal steel expanded mesh digunakake ing macem-macem lapangan, kayata bengkel, kapal, langit-langit, jubin, trotoar, pedal, tutup trench, pinggir conveyor, pager, etc.

| Ketebalan lembaran (mm) | Opening ing Jembar | Opening ing Length | Strand Jembar (mm) | Gulung Jembar | Gulung dawa | Bobot |

| 0.5 | 2.5 | 4.5 | 0.5 | 0.5 | 1 | 1.8 |

| 0.5 | 10 | 25 | 0.5 | 0.6 | 2 | 0.73 |

| 0.6 | 10 | 25 | 1 | 0.6 | 2 | 1 |

| 0.8 | 10 | 25 | 1 | 0.6 | 2 | 1.25 |

| 1 | 10 | 25 | 1.1 | 0.6 | 2 | 1.77 |

| 1 | 15 | 40 | 1.5 | 2 | 4 | 1.85 |

| 1.2 | 10 | 25 | 1.1 | 2 | 4 | 2.21 |

| 1.2 | 15 | 40 | 1.5 | 2 | 4 | 2.3 |

| 1.5 | 15 | 40 | 1.5 | 1.8 | 4 | 2.77 |

| 1.5 | 23 | 60 | 2.6 | 2 | 3.6 | 2.77 |

| 2 | 18 | 50 | 2.1 | 2 | 4 | 3.69 |

| 2 | 22 | 60 | 2.6 | 2 | 4 | 3.69 |

| 3 | 40 | 80 | 3.8 | 2 | 4 | 5.00 |

| 4 | 50 | 100 | 4 | 2 | 2 | 11.15 |

| 4.5 | 50 | 100 | 5 | 2 | 2.7 | 11.15 |

| 5 | 50 | 100 | 5 | 1.4 | 2.6 | 12.39 |

| 6 | 50 | 100 | 6 | 2 | 2.5 | 17.35 |

| 8 | 50 | 100 | 8 | 2 | 2.1 | 28.26 |

Wektu kirim: Jul-14-2021